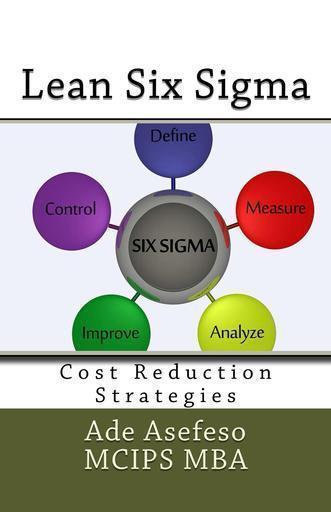

Lean Six Sigma: Cost Reduction Strategies

Lean Six Sigma: Cost Reduction Strategies

By Ade Asefeso MCIPS MBA

Copyright 2014 by Ade Asefeso MCIPS MBA

All rights reserved.

Second Edition

ISBN-13: 978-1499775075

ISBN-10: 1499775075

Publisher: AA Global Sourcing Ltd

Website: http://www.aaglobalsourcing.com

Disclaimer

This publication is designed to provide competent and reliable information regarding the subject matter covered. However, it is sold with the understanding that the author and publisher are not engaged in rendering professional advice. The authors and publishers specifically disclaim any liability that is incurred from the use or application of contents of this book.

If you purchased this book without a cover you should be aware that this book may have been stolen property and reported as “unsold and destroyed” to the publisher. In this case neither the author nor the publisher has received any payment for this “stripped book.”

Dedication

This book is dedicated to the hundreds of thousands of incredible souls in the world who have weathered through the up and down of recent recession.

To my family and friends who seems to have been sent here to teach me something about who I am supposed to be. They have nurtured me, challenged me, and even opposed me…. But at every juncture has taught me!

This book is dedicated to my lovely boys, Thomas, Michael and Karl. Teaching them to manage their finance will give them the lives they deserve. They have taught me more about life, presence, and energy management than anything I have done in my life.

Section 1: Lean Six Sigma

Chapter 1: Introduction

What does is Lean Six Sigma?

Lean Six Sigma is a synergised managerial concept of Lean and Six Sigma that results in the elimination of the seven kinds of wastes/muda (classified as Defects, Overproduction, Transportation, Waiting, Inventory, Motion and over Processing) and provision of goods and service at a rate of 3.4 defects per million opportunities (DPMO).

Six Sigma seeks to improve the quality of process outputs by identifying and removing the causes of defects (errors) and minimizing variability in manufacturing and business processes. It uses a set of quality management methods, including statistical methods, and creates a special infrastructure of people within the organization ("Black Belts", "Green Belts", etc.) who are experts in these methods. Each Six Sigma project carried out within an organization follows a defined sequence of steps and has quantified financial targets (cost reduction and/or profit increase).

The term Six Sigma originated from terminology associated with manufacturing, specifically terms associated with statistical modelling of manufacturing processes. The maturity of a manufacturing process can be described by a sigma rating indicating its yield, or the percentage of defect-free products it creates. A six sigma process is one in which 99.99966% of the products manufactured are statistically expected to be free of defects (3.4 defects per million). Motorola set a goal of "six sigma" for all of its manufacturing operations, and this goal became a byword for the management and engineering practices used to achieve it.

Lean Six Sigma utilises the DMAIC phases similar to that of Six Sigma. The Lean Six Sigma projects comprise the Lean's waste elimination projects and the Six Sigma projects based on the critical to quality characteristics. The DMAIC toolkit of Lean Six Sigma comprises all the Lean and Six Sigma tools. The training for Lean Six Sigma is provided through the belt based training system similar to that of Six Sigma. The belt personnel are designated as Green Belts, Black Belts and Master Black Belts.

Lean Six Sigma at many organizations simply means a measure of quality that strives for near perfection. But the statistical implications of a Lean Six Sigma program go well beyond the qualitative eradication of customer-perceptible defects. It’s a methodology that is well rooted in mathematics and statistics.

The objective of Lean Six Sigma Quality is to reduce process output variation so that on a long term basis, which is the customer’s aggregate experience with our process over time, this will result in no more than 3.4 defect Parts per Million (PPM) opportunities (or 3.4 Defects Per Million Opportunities – DPMO). For a process with only one specification limit (Upper or Lower), this results in six process standard deviations between the mean of the process and the customer’s specification limit (hence, 6 Sigma). For a process with two specification limits (Upper and Lower), this translates to slightly more than six process standard deviations between the mean and each specification limit such that the total defect rate corresponds to equivalent of six process standard deviations.

Many processes are prone to being influenced by special and/or assignable causes that impact the overall performance of the process relative to the customer’s specification. That is, the overall performance of our process as the customer views it might be 3.4 DPMO (corresponding to Long Term performance of 4.5 Sigma). However, our process could indeed be capable of producing a near perfect output (Short Term capability, also known as process entitlement of 6 Sigma).

The difference between the “best” a process can be, measured by Short Term process capability, and the customer’s aggregate experience (Long Term capability) is known as Shift depicted as Zshift or sshift. For a “typical” process, the value of shift is 1.5; therefore, when one hears about “6 Sigma,” inherent in that statement is that the short term capability of the process is 6, the long term capability is 4.5 (3.4 DPMO – what the customer sees) with an assumed shift of 1.5. Typically, when reference is given using DPMO, it denotes the Long Term capability of the process, which is the customer’s experience. The role of the Six Sigma professional is to quantify the process performance (Short Term and Long Term capability) and based on the true process entitlement and process shift; establish the right strategy to reach the established performance objective

As the process sigma value increases from zero to six, the variation of the process around the mean value decreases. With a high enough value of process sigma, the process approaches zero variation and is known as ‘zero defects.’

Statistical Take Away

Decrease your process variation (remember variance is the square of your process standard deviation) in order to increase your process sigma. The end result is greater customer satisfaction and lower costs.

Chapter 2: The History of Six Sigma

Six Sigma has evolved over time. The concepts behind Six Sigma can be traced through the centuries as the method took shape into what it is today.

The roots of Six Sigma as a measurement standard can be traced back to Carl Frederick Gauss (1777-1855) who introduced the concept of the normal curve. Six Sigma as a measurement standard in product variation can be traced back to the 1920′s when Walter Shewhart showed that three sigma from the mean is the point where a process requires correction. Many measurement standards (Cpk, Zero Defects, etc.) later came on the scene but credit for coining the term “Six Sigma” goes to a Motorola engineer named Bill Smith. (Incidentally, “Six Sigma” is a federally registered trademark of Motorola).

Six Sigma originated as a set of practices designed to improve manufacturing processes and eliminate defects, but its application was subsequently extended to other types of business processes as well. In Six Sigma, a defect is defined as any process output that does not meet customer specifications, or that could lead to creating an output that does not meet customer specifications.[3]

The core of Six Sigma was “born” at Motorola in the 1970s out of senior executive Art Sundry's criticism of Motorola’s bad quality. As a result of this criticism, the company discovered a connection between increases in quality and decreases in costs of production. At that time, the prevailing view was that quality costs extra money. In fact, it reduced total costs by driving down the costs for repair or control. Bill Smith subsequently formulated the particulars of the methodology at Motorola in 1986. Six Sigma was heavily inspired by the quality improvement methodologies of the six preceding decades, such as quality control, Total Quality Management (TQM), and Zero Defects, based on the work of pioneers such as Shewhart, Deming, Juran, Crosby, Ishikawa, Taguchi, and others.

In the early and mid-1980s with Chairman Bob Galvin at the helm, Motorola engineers decided that the traditional quality levels measuring defects in thousands of opportunities didn’t provide enough granularities. Instead, they wanted to measure the defects per million opportunities. Motorola developed this new standard and created the methodology and needed cultural change associated with it. Six Sigma helped Motorola realize powerful bottom-line results in their organization in fact; they documented more than $16 Billion in savings as a result of our Six Sigma efforts.

Since then, hundreds of companies around the world have adopted Six Sigma as a way of doing business. This is a direct result of many of America’s leaders openly praising the benefits of Six Sigma. Leaders such as Larry Bossidy of Allied Signal (now Honeywell), and Jack Welch of General Electric Company. Rumor has it that Larry and Jack were playing golf one day and Jack bet Larry that he could implement Six Sigma faster and with greater results at GE than Larry did at Allied Signal. The results speak for themselves.

Six Sigma has evolved over time. It’s more than just a quality system like TQM or ISO. It’s a way of doing business. As Geoff Tennant describes in his book Six Sigma: SPC and TQM in Manufacturing and Services: “Six Sigma is many things, and it would perhaps be easier to list all the things that Six Sigma quality is not. Six Sigma can be seen as a vision; a philosophy; a symbol; a metric; a goal; a methodology.” I couldn’t agree more.

Chapter 3: History of the Six Sigma Black Belt Naming Convention

Not surprisingly, the term Black Belt has its roots in the exotic realm of martial arts. Like a person skilled in the Oriental sport of karate, the Six Sigma Black Belt is self-assured and knowledgeable, the result of intensive training and real-world experience.

Motorola, the company that holds the Six Sigma trademark, says the data-driven defect-reduction process has saved the company more than $16 billion over the past 15 years. Six Sigma has generated similarly stunning results at companies here and abroad in the manufacturing, transactional, and service sectors. All businesses regardless of sector, size, or project link their success to one factor. In Six Sigma manner of speaking, it’s the Black Belt.

The term Black Belt refers to project leaders, skilled in the use of statistical methods and interpersonal communication, and dedicated to using Six Sigma methods to ensure customer satisfaction. Green Belts require less training than Black Belts and take responsibility for leading fewer projects, while Master Black Belts spend nearly all of their time consulting, mentoring, and training Green Belts and Black Belts.

Not surprisingly, the term Black Belt has its roots in the exotic realm of martial arts. Like a person skilled in the Oriental sport of karate, the Six Sigma Black Belt is self-assured and knowledgeable, the result of intensive training and real-world experience. The Six Sigma Black Belt is disciplined, purposeful, and decisive, able to lead highly focused efforts aimed at improving a company’s bottom line. And, to ensure continued improvement, the Black Belt works affirmatively to identify and mentor new Black Belts.

The evocative term is not without its detractors, however. For some, martial arts is synonymous with violence, attack mode, and bravado, all of which run counter to the term’s intended meaning: a methodically executed self-defence. Some companies have changed the names of their process improvement change leaders to move away from these images. Raytheon, for example, has replaced the words Black Belt with Expert, as in Six Sigma Expert and Six Sigma Master Expert. Mount Carmel Health System refers to Black Belts as Guides, and Master Black Belts as Master Guides. Countrywide Financial Corporation has left the Six Sigma and Belt terminology completely behind; instead, they refer to Master Black Belts, Black Belts and Green Belts as Gold, Silver, and Bronze certification levels, respectively. The Vanguard Group has even gone as far as to call their process improvement efforts “Unmatchable Excellence,” although much is based on the Six Sigma methodology.

While the late Bill Smith, a Motorola senior engineer and scientist, commonly gets credit for initiating the Six Sigma concept, the wordsmith who originated the belt argot is Dr. Mikel Harry. In 1986-1987 Harry, on authorized sabbatical from Motorola, spent three months at the Unisys Salt Lake Printed Circuit Facility, where he worked as a technical consultant with Unisys facility manager Clifford Ames. Harry’s mission was to solve a costly circuit board production problem.

According to Harry, once the problem was solved, Ames asked him to train others at Unisys. Harry referred to those he trained as process characterization experts, the term he had previously used for trainees at the Motorola Government Electronics Group. Harry remembers brainstorming with Ames to come up with something a little catchier. When Harry suggested Black Belts, Ames responded enthusiastically: “That’s sexy! I can sell that.” And the rest, as they say, is history.

Because a team approach is the norm among Motorola scientists and engineers, the belt-naming convention may appear to some to have occurred over time and osmotically among Motorola executives. However, Harry cites contracts, reports, and other artifacts that document the terminology’s introduction and implementation. The belt terminology, first articulated in a 1988 contract between Unisys and Harry, appears that same year in strategy papers from the first Unisys Black Belt trainees. Harry says he formally introduced the terminology to Motorola in a 1989 white paper, A Strategic Vision for accelerating the implementation of Six Sigma at Motorola, a paper he prepared for then CEO Robert Galvin.

By the early 1990s, the Black Belt nomenclature was hot. Recently retired Quality Director John Lupienski complements Harry’s version of the origins of Black Belt terminology in a time line Lupienski prepared for a 1990s Motorola Six Sigma presentation. Lupienski, who participated in Motorola’s first Quality Council meetings with Bill Smith and Jack Germain (Motorola’s first Vice President of Quality), says the Black Belt program began in 1990 with the organization of a DOE symposium committee. Additional Motorola employees who were present at this time verify these facts.

The following year, Harry established Motorola’s Six Sigma Research Institute, which he had proposed in his 1989 Strategic Vision white paper, and served as its founding Director and a senior member of the technical staff. The Institute, a research and testing site, offered a reasonable alternative to the factory floor for simulations and statistical problem solving. As the Institute’s Director, Harry relied on the Black Belt framework to move Six Sigma methodology across the corporation.

Harry successfully nurtured the Black Belt model, encouraging other companies to implement it in 1992. Harry says he persuaded those other companies like Texas Instruments, IBM, Kodak, Digital Equipment, and Asea Brown Boveri to share expertise and work with Motorola and the Institute to craft a mutually beneficial training program.

David Hallowell, the Digital representative at that time, recalls the common Black Belt curriculum that the consortium identified, developed and piloted. The statistical part of the body of knowledge was easy to see, but a key insight was the inclusion of a healthy measure of soft skills to deal with the change management, business awareness, and team dynamics critical to real Six Sigma success. The Six Sigma Technical Institute was soon deploying that training for Black Belt candidates. By the end of 1992, the first half-dozen Six Sigma Black Belts had gained recognition in Asia and the United States.

The Black Belt jargon has stuck. In fact, an online Google search for Six Sigma generates a whopping 565,000 keyword matches, many of them about Black Belt training. Just as Six Sigma has outlived early scepticism about its long-term survival, the Green Belt/Black Belt/Master Black Belt designations have emerged as generally accepted business terminology.

Chapter 4: Remembering Bill Smith, Father of Six Sigma

Bill Smith, the Father of Six Sigma, introduced the statistical approach while working at Motorola, where it garnered the company financial benefits and numerous awards.

Bill Smith spent years convincing higher-ups that he really had invented a better mousetrap. Then he spent the rest of his life spreading the word to business professionals, government leaders and educators.

Smith’s mousetrap? It was Six Sigma, the TQM spin off that has generated billions of dollars for Motorola, the company where Smith introduced his statistical approach aimed at increasing profitability by reducing defects. Smith, who earned the appellation, Father of Six Sigma, would probably be tickled to know Six Sigma has become so mainstream that it even appears periodically in the widely syndicated comic strip, Dilbert.

As a Motorola employee, Smith did not share directly in the profits generated by the company’s Six Sigma applications. However, over the years, he and Motorola garnered numerous awards and recognition for his vital work to improve profitability in America’s manufacturing sector. He was especially proud of his role in Motorola’s winning the prestigious Malcolm Baldrige National Quality Award. The Baldrige Award came in 1988, two years after Motorola implemented Smith’s Six Sigma principles.

Smith’s death, only five years later, caught everyone by surprise. He died of a heart attack at work.

Daughter Marjorie Hook, now 37 and president of Clarksville Consulting Group in Austin, Texas, developed an affinity for Six Sigma and occasionally collaborated with her father for a few years after college. Hook said winning the Baldrige Award stands out as a career high point in her father’s life.

“He was thrilled that a good thing was happening to Motorola and that Six Sigma had made such a difference,” she said. “He drafted Six Sigma long before [Motorola Executive Committee Chairman] Bob Galvin ever took it on board. So, for him, it was the culmination of so many years of work and trying to change the way people think about things. He finally had some phenomenal success at Motorola and he was getting great recognition for it.”

Baldrige Award winners agree to share their quality programs with anyone who is interested. Hook said that since Motorola was the first company to win, others were eager to learn more about Six Sigma. “That’s one of the primary reasons Six Sigma became so widely known,” she said.

“He got to spend the last few years of his life travelling around, teaching and introducing Six Sigma to people,” Hook said. “He was so appreciated wherever he went and people were really interested in it. When others started using Six Sigma and seeing results just like Motorola had, he was thrilled.”

Not surprisingly, the man behind the methodology was a passionate visionary and a great communicator. Bill Smith was also a perfectionist. Even at home.

“But not in an annoying way,” Hook said. “He just did everything the right way because that was the way to do it.

“I think that was just a natural part of his character,” she said. “It came through when he was repairing a watch or helping us with a science project or fixing a car or learning to play a musical instrument; he was incredibly talented. He knew how to do absolutely everything.”

Hook said he always approached projects methodically and drafted a plan, either on paper or in his mind. “He planned things out, making sure we had the skills and the tools, doing it, and then following through with the cleaning up,” Hook said. “Everything had to be done in a complete way. Nothing was ever done sort of off-hand. The standard was always so high.”

Bill Smith also made the most of leisure time. He and his wife, Betty, shared a love of music, especially when they were the musicians, she on the piano and he on the organ at their Barrington, Illinois home. However, she suspects he bought her a new baby grand piano to keep her occupied while he devoted spare time to working out statistical programs on his computer.

“One time when he was home in the evening, he had an idea of trading stock options,” Betty Smith recalled. “So he would do it on paper and then on the computer for awhile to see how it would work. And it worked very well. Imagine that!”

Bill Smith also used his computer to develop a program that would help him predict winning racehorses. Betty Smith said he programmed a calculator with data about the horses racing at Arlington International Racecourse in Arlington Heights, Illinois. “By golly, I think we won eight of the first nine, and people were following us around,” she said.

The Smiths soon joined half a dozen others in a horse-owning partnership, embarking on a lifelong hobby. “We had six horses when he died,” Betty Smith said. “They were ours, not part of a partnership. In the beginning, it was lucrative. I think one horse won most of the money. After Bill died, I got rid of all the horses except one. Her grandfather was Seattle Slew, the famous 1977 Triple Crown winner.”

Born in Brooklyn, New York, in 1929, Bill Smith graduated from the U.S. Naval Academy in 1952 and studied at the University of Minnesota School of Business. In 1987, after working for nearly 35 years in engineering and quality assurance, he joined Motorola, serving as vice president and senior quality assurance manager for the Land Mobile Products Sector.

In honour of Smith’s talents and dedication, Northwestern University’s Kellogg Graduate School of Management established an endowed scholarship in Smith’s name. Dean Donald P. Jacobs of the Kellogg School notified Motorola’s Robert Galvin of the school’s intention less than a month after Smith died. “Bill was an extremely effective and inspiring communicator,” Jacobs wrote in his July 27, 1993, letter. “He never failed to impress his audience by the depth of his knowledge, the extent of his personal commitment, and the level of his intellectual powers.” The school created the scholarship fund in recognition of Smith’s “contributions to Kellogg and his dedication to the teaching and practice of quality.”

It was a fitting tribute to a man who influenced business students and corporate leaders worldwide with his innovative Six Sigma strategy.

As the one who followed most closely in his footsteps, Marjorie Hook is well-positioned to speculate about Bill Smith’s take on the 2003 version of Six Sigma. “Today I think people sometimes try to make Six Sigma seem complicated and overly technical,” she said. “His approach was, ‘If you want to improve something, involve the people who are doing the job.’ He always wanted to make it simple so people would use it.”

And would he approve of Six Sigma’s evolution? “He’d be thrilled,” Hook said.

Many people say that it takes money to make money. In the world of Six Sigma quality, the saying also holds true: it takes money to save money using the Six Sigma quality methodology. You can’t expect to significantly reduce costs and increase sales using Six Sigma without investing in training, organizational infrastructure and culture evolution.

Sure you can reduce costs and increase sales in a localized area of a business using the Six Sigma quality methodology and you can probably do it inexpensively by hiring an ex-Motorola or GE Black Belt. I like to think of that scenario as a “get rich quick” application of Six Sigma. But is it going to last when a manager is promoted to a different area or leaves the company? Probably not. If you want to produce a culture shift within your organization, a shift that causes every employee to think about how their actions impact the customer and to communicate within the business using a consistent language, it’s going to require a resource commitment. It takes money to save money!

How much financial commitment does Six Sigma require and what magnitude of financial benefit can you expect to receive? We all have people that we must answer to and rhetoric doesn’t pay the bills or keep the stockholders happy (anymore). I was tired of reading web pages or hearing people say:

“Companies of all types and sizes are in the midst of a quality revolution. GE saved $12 billion over five years and added $1 to its earnings per share. Honeywell (AlliedSignal) recorded more than $800 million in savings.”

“GE produces annual benefits of over $2.5 billion across the organization from Six Sigma.”

“Motorola reduced manufacturing costs by $1.4 billion from 1987-1994.”

“Six Sigma reportedly saved Motorola $15 billion over the last 11 years.”

The above quotations may in fact be true, but pulling the numbers out of the context of the organization’s revenues does nothing to help a company figure out if Six Sigma is right for them. For example, how much can a $10 million or $100 million company expect to save?

I investigated what the companies themselves had to say about their Six Sigma costs and savings. I didn’t believe anything that was written on third party websites, was estimated by “experts,” or was written in books on the topic. I reviewed literature and only captured facts found in annual reports, website pages and presentations found on company websites.

While recent corporate events like the Enron and WorldCom scandals might lead us to believe that not everything we read in a company’s annual report is valid, I am going to provide the following information based on the assumption that these Six Sigma companies operate with integrity until proven otherwise.

I investigated Motorola, Allied Signal, GE and Honeywell. I choose these four companies because they are the companies that invented and refined Six Sigma; they are the most mature in their deployments and culture changes. As the Motorola website says, they invented it in 1986. Allied Signal deployed Six Sigma in 1994, GE in 1995. Honeywell was included because Allied Signal merged with Honeywell in 1999 (they launched their own initiative in 1998). Many companies have deployed Six Sigma between the years of GE and Honeywell I Will leave those companies for another Chapter in this book.

Chapter 5: Six Sigma is not a “Get Rich Quick” Methodology

Six Sigma is not a “get rich quick” methodology. I like to think of it like my retirement savings plan. Six Sigma is a get rich slow methodology the take-away point being that you will get rich if you plan properly and execute consistently.

As GE’s 1996 annual report states, “It has been estimated that less than Six Sigma quality, i.e., the three-to-four Sigma levels that are average for most U.S. companies, can cost a company as much as 10-15 percent of its revenues. For GE, that would mean $8-12 billion.” With GE’s 2001 revenue of $111.6 billion, this would translate into $11.2-16.7 billion of savings. Although $2 billion worth of savings in 1999 is impressive, it appears that even GE hasn’t been able to yet capture the losses due to poor quality or maybe they’re above the three-to-four Sigma levels that are the average for most U.S. companies?

In either case, 1.2-4.5 percent of revenue is significant and should catch the eye of any CEO or CFO. For a $30 million a year company, that can translate into between $360,000 and $1,350,000 in bottom-line-impacting savings per year. It takes money to make money. Is investing in Six Sigma quality, your employees and your organization’s culture worth the money? Only you and your executive leadership team can decide the answer to that question.

The man whose ideas led to corporations adopting Six Sigma and other quality management strategies warns that U.S and UK. companies are moving too slowly in improving the quality of business procedures, products and services. These nations position in the world economy is at risk, according to Dr. Joseph M. Juran.

Juran, dean of quality professionals worldwide, told an audience which had come to Stamford, Connecticut (USA) to mark his 100th year and the Juran Institute’s 25th anniversary: “The U.S. improvement of quality has been evolutionary, not revolutionary. We have exported jobs and lost entire industries. If these standards continue, there will be a severe risk that the U.S. will lose its status as an economic superpower.”

Pressing the issue of quality as he has for decades, Juran made his remarks at a luncheon in his honour. Family, friends and numerous business executives who have benefited from his advice celebrated his 100th birthday, which actually comes on Dec. 24. They also recognized the institute he established in 1979 to address quality management issues. The institute is located in Wilton, Connecticut (USA).

Chief executives should personally become leaders of their companies’ quality control efforts, Juran said. He credited Motorola for starting its own quality control university in the 1980s and blazing the trail in the Six Sigma management strategy.

Juran’s Role in Japanese Leadership in Quality

Japanese industrialists established quality measures as a business priority in the 1950s and 1960s. Leaders among those Japanese industrialists have given great credit to Juran for advice he first gave them in 1954 during a presentation he made in Japan. Although Juran was the one who delivered the message, along with another American management icon, W. Edwards Deming, it is the Japanese who deserve the credit for incorporating the ideas into their manufacturing and quality control processes, Juran said.

“They knew they needed help. They listened, and they translated my books into Japanese. I gave lectures like that in a lot of countries, but they took it a lot further,” Juran said. The result was a nation that incorporated quality management into nearly every facet of business, distancing Japan from the rest of the world, he said.

“The United States is not the world leader in quality. The leader is Japan. Before World War II it was the exporter of shoddy goods,” Juran told the audience. “They tried to gain power through trade. Their executives knew they had to improve their quality. The rest is history.”

Juran’s message about quality management resonated among top executives at those Japanese businesses, according to Noriaku Kano, engineering professor in the Department of Industrial Management and Engineering at Tokyo University of Science. Kano, a well-known name in quality management himself, travelled from Tokyo for the Juran celebration.

“It was important to the development of Japan,” said Kano, who was a graduate student in Japan when he first met Juran in 1966. In fact, Juran developed such a reputation among Japanese industrialists that he was decorated by the emperor, said Kano, one of a series of speakers who had stories to tell about their dealings with Juran and his institute, which specializes in working with corporations and non-profits on quality management issues.

Quality Leaders Worldwide Praise Juran’s Contributions

Curt Reimann, former director of the Malcolm Baldridge National Quality Award and retired director for quality programs at the National Institute of Standards and Technology, recalled Juran’s testimony before Congress about Japan’s emphasis on quality as its way to compete in the world economy. “I think there was a great deal of hand wringing, but there needed to be action,” Reimann said. Hence the Baldridge competition was started in 1986, with the assistance of Juran as a member of the award’s board of overseers.

A. Blanton Godfrey, a former chief executive officer of the Juran Institute and dean of the School of Textiles at North Carolina State University, contended that U.S. companies made a crucial error by not adopting Juran’s philosophies in the 1950s when the Japanese saw the benefits. “It was productivity in the 1950s and not quality. The objective wasn’t making it good. It was making it fast,” Godfrey said. “The Japanese listened and became exporters.”

“I had no idea in 1924 that the subject of managing for quality would, during my lifetime, expand in importance, become a growth industry, and undergo a wrenching world revolution. Yet it did.” - Dr. Joseph M. Juran

One of Juran’s pupils, Enrique Maso, travelled to the celebration from Barcelona, Spain, to thank Juran for his tutelage. Maso recalled a day in 1949 when he spent five hours in Washington Square in New York City, discussing business management with Juran, who at the time was an instructor at New York University. “I owe everything to Professor Juran,” said Maso, who became a major player in several Spanish industries and served as the mayor of Barcelona.

Lennart Sandholm of Sweden-based Sandholm Associates told the audience that he already was familiar with Juran’s strategies when he met Juran in 1965 while a quality control manager at Electrolux in Sweden. He tried to attend Juran’s seminars whenever one was being held in Sweden. In all, Juran made 31 visits to Sweden. “The visits that you made laid a foundation for a long friendship,” Sandholm told Juran, adding that he has been an inspiration to Swedish companies. “You are the person outside of my family that has had the greatest influence on my life,” Sandholm said.

David Hutchins, a principal in David Hutchins International Limited, came to the celebration from the United Kingdom. He recalled that Juran was speaking to him and others in London the day Indira Ghandi was assassinated in October 1984. Even though a noisy crowd assembled in the street outside the building, Juran kept his commitment, speaking over the tumult.

Juran’s ideas have been adopted by many major corporations in the U.S., Japan, Spain, Sweden, the United Kingdom and Canada, according to Joseph DeFeo, the current president and CEO of the Juran Institute. DeFeo met Juran in 1985 when he was a manager at Perkin Elmer. “The values he taught us saved that company for about 20 years,” said DeFeo, who helped organize the fete for Juran. Under DeFeo’s leadership, the institute carries on Juran’s legacy by helping organizations around the world improve their business management techniques.

Chapter 6: Quality Guru’s Life Had a Humble Beginning

What do I have in common with Juran? Is humble beginning!

Juran, who now lives in Rye, New York (USA) with Sadie, his wife of 77 years, immigrated to Minneapolis, Minnesota (USA), before World War I with his mother and five siblings from a small town in the former Austro-Hungarian Empire. His father had preceded the family to the United States three years earlier.

A display outside the meeting room provided guests with an in-depth look at Juran’s life, including a copy of his birth certificate, photographs of the Romanian village where he was born and the modest house where he lived with his family in Minnesota. A portrait taken at the time of Juran’s graduation from East High School in Minneapolis in 1917 revealed a handsome young man with an eager look, ready to contribute to his adopted homeland.

Like many of that era, Juran worked at a variety of jobs, including labourer, shoe salesman, bootblack, grocery clerk and bookkeeper. But unlike most of his peers, he decided to seek a college degree and in 1920 enrolled at the University of Minnesota. He graduated with a degree in electrical engineering and later earned a law degree. Years later, he showed his appreciation to the university by funding what became the Juran Centre for Quality Improvement. The university has established a fellowship in his honour, focused on promoting quality in business.

Juran’s career has included a stint as head of industrial engineering at Western Electric in the late 1930s, serving as a lend-lease assistant administrator during World War II and later his dedication to consulting on quality management. In 1937, with his conceptualization of the Pareto Principle, Juran became a source for those in business management.

Juran’s Quality Handbook, which he wrote in 1951, is now in its fifth printing. His book, Managerial Breakthrough, first published in 1964, presented a more general theory of quality management, which evolved into Six Sigma – a quality management process adopted by Motorola, General Electric and now many other corporations. Many of the 200 celebrants at the luncheon carried Juran’s most recent book, Architect of Quality, his autobiography which was published by McGraw-Hill last year.

Juran continues to write about issues and fundamentals in managing for quality, and is planning another book.

After he established the Juran Institute at age 74, one of the first projects was development of a video series on quality improvement that was distributed to companies around the world. “Probably a million people listened to those tapes,” Juran said. He finally relinquished the role of leading the institute in 1987, allowing him time to continue lecturing.

Juran Comes from a Family of Achievers

Speaking concisely in a clear tone that belied his age, Juran informed the luncheon audience that he comes from a family of achievers. He introduced his son, Charles, who made a career in agricultural real estate; his daughter, Sylvia, who earned a doctorate in Russian literature; and a cadre of grand children and great-grandchildren who are involved in a variety of professions or are in college.

For Charles Juran, 73, the day was one of celebration and one of memories. “I was brought up to believe in the American dream,” he said. “I saw it materialize in our family.” He noted that his Uncle Nathan became an Oscar-winning film director, his Aunt Minerva earned a doctoral degree and had a career in education, and his Uncle Rudy founded a municipal bond company. “All of that talent out of that little shack,” he mused.

“It was a hard life for my father as a child. There was little difference between the poverty in Minneapolis and in Romania. This is not a personal story of achievement,” he said. “It’s an American story.”

Chapter 7: Should you Calculate your Process Sigma?

Practitioners must learn when and how to calculate the sigma level of a process.

Many people hear about the Six Sigma quality methodology and immediately want to calculate their own process sigma to determine how close (or far) they are from six sigma. My immediate response to them is twofold:

Are you currently measuring your process capability?

Are you satisfied with your performance?

If the answer to both is yes, then calculating your process sigma may be interesting but not necessary.

When Process Sigma is Not Necessary

Let me illustrate with an example. A power company measures their performance in uptime of available power to their grid. Every minute of potential uptime (power is available) is an opportunity, every minute of downtime (power is not available) is a defect in the eyes of a customer. Data is continuously taken, the process capability is measured, and the yield is calculated to be 99.9%. The power company is satisfied with their current performance (but always looking to improve), and the customer’s needs (as collected via Voice of the Customer) are being met.

If the entire company communicates in yield and everyone within the company understands this language, is determining the process sigma level useful? I submit that if the company is pursuing full implementation of the Six Sigma quality methodology across the organization then calculating sigma is appropriate because processes within the organization and between plants can be compared. When a company is only considering Six Sigma for one functional area (power transmission OR bill collection OR call centre) then the company might be better suited to maintain the metrics that everyone currently uses and understands.

How can an organization communicate if everyone doesn’t learn the language?

I know what you’re thinking, ‘Ok Ade, get on with it. I want to calculate my process sigma anyway. How can I do it?’ Here is your two minute instruction on calculating your process sigma.

How to Calculate Process Sigma

Consider the power company example from the previous page: A power company measures their performance in uptime of available power to their grid. Here is the 5 step process to calculate your process sigma.

Step 1: Define your Opportunities

An opportunity is the lowest defect noticeable by a customer. This definition, of course, is debatable within the Six Sigma community. Here’s a useful snippet from fellow professionals discussing this point:

“Typically, most products (and services) have more than one opportunity of going wrong. For example, it is estimated than in electronics assembly a diode could have the following opportunities for error: 1) Wrong diode and 2) wrong polarity (inserted backwards), so for each assembly shipped, at least two defect opportunities could be assigned for each diode. Apparently, some manufacturers of large complex equipment with many components prefer to count two opportunities in this case. My point is that this approach dilutes Six Sigma metrics.” -Anonymous

Many Six Sigma professionals support the counter point. I always like to think back to the pioneer of Six Sigma, Motorola. They built pagers that did not require testing prior to shipment to the customer. Their process sigma was around six, meaning that only approximately 3.4 pagers out of a million shipped did not function properly when the customer received it. The customer doesn’t care if the diode is backwards or is missing, just that the pager works.

Returning to our power company example, an opportunity was defined as a minute of uptime. That was the lowest (shortest) time period that was noticeable by a customer.

Step 2: Define your Defects

Defining what a defect is to your customer is not easy either. You need to first communicate with your customer through focus groups, surveys, or other voice of the customer tools. To Motorola pager customers, a defect was defined as a pager that did not function properly.

Returning to our power company example, a defect is defined by the customer as one minute of no power. An additional defect would be noticed for every minute that elapsed where the customer didn’t have power available.

Step 3: Measure your Opportunities and Defects

Now that you have clear definitions of what an opportunity and defect are, you can measure them. The power company example is relatively straight forward, but sometimes you may need to set up a formal data collection plan and organize the process of data collection. Be sure to read ‘Building a Sound Data Collection Plan' to ensure that you gather reliable and statistically valid data.

Returning to our power company example, here is the data we collected:

Opportunities (last year): 525,600 minutes

Defects (last year): 500 minutes

Step 4: Calculate your Yield

The process yield is calculated by subtracting the total number of defects from the total number of opportunities, dividing by the total number of opportunities, and finally multiplying the result by 100.

Returning to our power company example, the yield would be calculated as: ((525,600 – 500) / 525,600) * 100 = 99.90%.

Alternatively, the yield can be calculated for you by using the iSixSigma Process Sigma Calculator – just input your process opportunities and defects.

Step 5: Look Up Process Sigma

The final step (if not using the iSixSigma Process Sigma Calculator) is to look up your sigma on a sigma conversion table, using your process yield calculated in

Step 4: Assumptions

No analysis would be complete without properly noting the assumptions that you have made. In the above analysis, we have assumed that the standard sigma shift of 1.5 is appropriate (the calculator allows you to specify another value), the data is normally distributed, and the process is stable. In addition, the calculations are made with using one-tail values of the normal distribution.

Chapter 8: A Method for Aligning the Six Sigma Performance Metric

Some Six Sigma practitioners are concerned about the current method used to calculate Z-scores and express process capability. A proposed modification, based on Berryman’s scorecard, may fill the need for a more intuitive and business savvy metric.

The common terminology for describing the capability of a business process is process sigma, or Z-score. Z-scores provide a universal standard performance metric for vastly different processes. According to this standard, a process sigma of 6.0 equates to 3.4 defects per million opportunities (DPMO). This value is obtained by accounting for the fact that any process in control continues to allow for a drift of about 1.5 sigma. The traditional calculation method results in the following Z-scores for error free processes.

0 percent error-free yield = negative infinity Z-score

50 percent error-free yield = 1.5 Z-score

99.99966 percent error-free yield = 6.0 Z-score

100 percent error-free yield = positive infinity Z-score

Some Six Sigma practitioners have raised concerns about the current calculation method and the need to develop a more intuitive Z-score. Because a 50 percent error-free yield does not equal a Z-score of zero, the range of Z-scores from negative infinity to positive infinity gives a false sense of symmetry. The asymmetry is due to the belief that any long-term process variability changes by about 1.5 sigma from its short-term variation.

In addition to the asymmetry in the measurement system, there are questions about the appropriateness of using a negative sigma value. While the method and logic used for negative Z-scores is clear, the intuitive meaning of them is not. What does the negative sigma value mean? What is the meaning of a Z-score of zero? As a manager, how should you react to improvements and reward sigma value gains? While the mathematically minded will argue that it is simply a definition, the fact that questions are raised about its appropriateness puts forth a challenge to the Six Sigma community to develop a metric that makes engineering as well as business sense.

The Need for Change

Recently, a Six Sigma team presented their results for a project where the initial process yield was very low, resulting in a low sigma value. A small effort by the project team, however, made a significant change in the sigma score. The management team was excited about the project team’s work. But their excitement was not as high for another project where the team was charged with making an improvement within an already high-performing process. The current Z-score calculation method does not provide a clear reflection of the effort required to improve processes at various levels of initial sigma value.

This begs the questions.

Should practitioners use a metric that is more intuitive in understanding the initial and subsequent change in sigma value?

Should the metric account for the relative effort required to achieve the improvement?

Chapter 9: The Champion's Role in Successful Six Sigma Deployments

Champions have a much larger role in deploying Six Sigma or any other initiative than just removing roadblocks. Champions must be integrated into the business; select projects accurately, adjust the speed of the deployment as necessary, and take responsibility for implementation.

For a Six Sigma deployment to produce the expected results, organizational roles and responsibilities must be clearly defined and aligned. If Executives and Champions are trained and Black Belts and Green Belts aren’t, the probability of success decreases to virtually nothing. The reverse is true as well. None of these situations will produce the type of results that will occur when Six Sigma practitioners are placed in the correct support environment.

The Six Sigma Support Structure

The core structure at an operational level is Black Belts supported by Master Black Belts. The Black Belts are trained in the basic problem-solving strategy and methodology. When Black Belts have demonstrated a proclivity for solving difficult projects, are self-starters, are self-reliant to a reasonable extent and put in the time commensurate with the task, they are considered for additional training as Master Black Belts. There is no universally accepted standard for the Master Black Belt curriculum. Additional training is intended to broaden, not necessarily raise the level of, the tool sets that are at the disposal of Master Black Belts. The strategy is to provide Master Black Belts with a wider array of skill sets so they can assist in projects that may become stalled.

Six Sigma Green Belts are critical to the process because they are the key to creating a culture shift. If the shift is attempted by training huge numbers of Black Belts, Black Belts will spend most of their time tripping over each other as they scramble to create the “number of projects” or “dollars saved” metrics imposed by management to motivate them.

A popular theory is that in a change process, one-third is on the fence, one-third is holding back, and one-third is jumping at the new opportunity. These numbers will fluctuate based on the company culture. A conservative company culture will create more fence sitters and resistors. A dynamic company culture will increase the number of people jumping at the new opportunity. Before you can comprehend what the number actually is, you must understand the company culture. Green Belts, in the long run, are the ones who shift the culture.

The relationship between Master Black Belts, Black Belts and Green Belts is well understood due to the intuitive nature of the titles. Getting just this much of the structure bolsters the success model. So what is the rest of the structure?

In most organizations they are referred to as Champions. If you ask people what a Champion does, they will quickly reply, “they remove roadblocks.” Superficially, that is true. Champions should remove roadblocks. Champions need to be in a position to defuse any issues that may arise between a Black Belt and another person in the organization, particularly if the issue is with someone with a higher formal position in the company. The Champion should be the buffer that keeps a Black Belt out of a head-to-head confrontation with Managers, Vice Presidents and Directors in the company, allowing Black Belts the freedom to focus on the problem, not engage in some inane territorial dispute. This is the most fundamental function of the Champion.

Chapter 10: The Extended Six Sigma Champion

One critical characteristic for successful Six Sigma Champions is that they are some hybrid of Henry Kissinger and Xena, the Warrior Princess. It may actually be easier to find the mutant offspring of these two leaders than it is to find the complete Champion. Being the complete Champion requires more than diplomatic and warrior skill sets.

Champions must be proficient in four other areas:

Business and operations interface

Project selection

Pace mediation

Results implementation

Business and Operations Interface

Champions should know the business they are in and at least be familiar with the technology used in the process. Black Belts are the process/project subject matter experts. Champions must constantly guard against intruding into the process and offering solutions. One of the Champion’s primary roles is to assure that operational level projects are aligned with the strategic level business objectives. Project reviews should be conducted not as a tool to manage Black Belts but to assure that the project is progressing as planned and that the result will produce a result that resembles (and aligns with) the needs of the organization. It can also be an opportunity for Champions to identify other potential areas of improvement.

Many companies have invoked the Balanced Score Card to assure this alignment. It is a good tool to apply metrics to Champions. It can be used as a measurement tool to quantify the performance of Champions in this role.

Six Sigma Project Selection

The basic task of assigning Six Sigma projects remains an enigma for some reason. This is the most fundamental skill of a manager with direct reports. When placed under the microscope of matching a project to a Black Belt, however, Champions will “stand frozen in the headlights.” You have to wonder if it is truly such a difficult task or if it is the public nature of their decision that causes them so much consternation. We have seen Black Belts in report-out situations where some top-level manager will remark, “Who picked that project?” This goes back to the Dr. Deming’s eighth point: “Drive out fear.” This seemingly innocuous remark will infuse fear deep into Champions’ hearts. Instead of viewing project selection as an opportunity to improve a part of the process, they perceive it as a potentially career-limiting opportunity. The management staff attending reviews should be coached by either their Six Sigma providers (consultants) or a person with a background in Organizational Development (OD) on how to interact with the people involved in the report-out.

Again, alignment is the key. If the organization truly understands and practices alignment, project selection becomes less of a threat. Furthermore, if the alignment is augmented with process data it is an even easier task. The threatening question is defused to become a discussion of the alignment methods or the data that was used. The personal implications become a non-issue.

Pace Mediation

At the onset of a Six Sigma deployment one or more people are selected to generate a deployment plan. This seems to come from one of two sources; the Six Sigma provider or the internal sponsor. There is an inherent issue with allowing a Six Sigma provider to formulate the plan; cost. If your Six Sigma provider is most concerned with enhancing their own financial position, you could be in trouble. If your Six Sigma provider is more concerned with creating a successful deployment and letting reputation provide the incremental business, you should be fine. In either situation it does not make much sense to abdicate complete control of company resources to a person with limited scope of your business operations.

One should also realize the risks associated with choosing an internal sponsor. The resulting plan will be a direct function of the sponsor’s level of Six Sigma knowledge. Many organizations have taken to hiring an Internal Master Black Belt to lead the organizational charge. The risk here is the same as previously mentioned: if the total deployment experience is one deployment, they still have a limited scope. It is the basic calculation for a confidence interval using attribute data and a sample size of one. It is better than zero but probably not a significant difference. The optimum Six Sigma deployment plan is derived from a combination of an internal expert (Business, Six Sigma and Change) and the Six Sigma provider.

Once a plan has been generated and sold at the C-Level it is difficult to modify. Internal people will rarely adjust the plan. Very few deployments are initiated with metrics that quantify the program’s results and lead to a decision to accelerate or slow the program. Slowing a Six Sigma initiative too much may cause it to die, no sense of urgency will deprioritize any initiative regardless of which initiative it is. The real issue comes from a person or persons so committed to driving a plan that they see only completion as the success metric. Frequently these programs are quantified in terms of numbers of people trained. This will turn the focus from a results-driven program to a training program.

When a plan is constructed it should have goals, specific targets that will increase customer success/satisfaction, competitive position, technology, etc. These should have metrics. Meeting or not meeting metrics should be analyzed, and adjustments should be made to the program.

Results Implementation

We have labelled Black Belts as Change Agents. Change agents inherit the responsibility for implementing projects with identified potential savings. In many cases the Black Belt project will be cross-functional, and cutting across departmental lines can be hazardous waters to navigate, not to mention the complete lack of formal authority that the Black Belt possesses in these situations. Green Belt projects may be less prone to this ailment, but it may affect them as well.

When a project is completed it should have a calculated potential savings. The finance department of the organization, not the Six Sigma provider, should sign off on this number. The savings should not only have a financial measurement but should also be time bounded. That number represents a reduction in wasted resources for the organization. It is a metric that the Champion should be held accountable for. If a project identifies a $50,000 savings over the next 12 months and it produces only $25,000 because the Champion took six months to get involved in the implementation, then the metric should reflect the lack of involvement. If the plan was executed perfectly and the financial projection was inaccurate, a metric should be in place to reflect that inaccuracy. Just as with anything else, the metrics will drive the performance. If you want accurate projections and timely implementations, you had better place a metric on them.

One of the biggest questions associated with Six Sigma project savings is “are they real.” A decision to credit soft savings opens the door to exaggerations. The audit functions in place in companies today should be of a wide enough scope to assure the accuracy of these numbers whether they are from a Six Sigma deployment or any other program that uses cost savings as a metric. The audit function does not necessarily lie within the accounting or finance departments. The process of calculating savings may be well defined, documented and incorporated into some type of Quality System (Business System) audit. Some of the larger companies have internal auditors who have been given responsibility for the accuracy of these numbers as well.

Champions have a much larger role in deploying Six Sigma or any other initiative than just removing roadblocks. The job requires more than just this single task. Champions must be integrated into the business; select projects accurately, adjust the speed of the deployment as necessary, and take responsibility for implementation.

Unless metrics are placed on all responsibilities of a Champion, the organization is placing the deployment at risk. Failure to execute these tasks at even a minimal level can and does propagate turnover of the people your organization spent valuable resources training.

Chapter 11: Six Critical Success Factors for a Six Sigma Deployment

Six Sigma is a powerful tool for solving business problems and driving excellence in organizations. Its benefits can include breakthrough improvements, cost savings, defect reduction, greater customer satisfaction, and higher productivity and efficiency. To reap these benefits, however, organizations must pay close attention to six key factors that can make or break a Six Sigma deployment.

Senior Management Involvement

Top management team members must show their support for the deployment. Simply sending emails is not enough; they must take the responsibility of leading from the front, through involvement in the following areas:

Selecting projects and teams

Reviewing project milestones

Approving improvement ideas

Resolving conflicts

Recognizing teams

For example, if an organization’s chief operating officer (COO) oversees support functions, such as HR, administration, training and finance, etc., the COO, as the sponsor, needs to be involved in projects from selection to closure.

Another important role for the top management is to resolve conflicts between Green Belts, Black Belts or process owners who are working on Six Sigma projects. Because of the power of their position, senior management team members should step in to diffuse situations.

Selection of Six Sigma Projects

When selecting a project, organizations need to make sure that the project has a manageable scope. If the perspective is too wide, the project will demand too many resources and take a long time to complete. As the project drags on, team members may lose interest mid-way through, thus reducing the chances of the project’s survival. By selecting projects with manageable scope, the organization will be able to demonstrate early wins, and the Six Sigma program will gain momentum and appreciation.

Another important factor that must be considered while selecting a Six Sigma project is the operational stability of the process. Consider this scenario: A team starts a project to reduce recruitment cycle time. The current process is influenced by the people doing the recruitment. However, the management team has decided to roll out a highly automated recruitment process within the next couple of months. Because of the drastic changes involved, it is easy to imagine that the project will be scrapped mid-way.

Selection of Project Teams

Many organizations find success by selecting a project leader who belongs to the operational process being improved and has a stake in that process. For example, appointing a member of the HR team to lead a project to bring improvements to a finance process simply because the HR team member is available can easily backfire. Sometimes it is worth appointing a co-project lead as a back-up. This is especially helpful if the project is focused on a process or function where the roles and responsibilities of team members change dynamically due to their customers’ needs.

Inclusion of Six Sigma Projects in Performance Appraisals

Another significant success factor is the inclusion of project efforts in the performance objectives of all team members working on a project. The objectives should be measurable and have clear deadlines. Communicating these objectives to all the team members and their managers at the beginning of the project will bring accountability and apply positive pressure on the team to deliver as planned.

Customization of Six Sigma to the Organization’s Culture

Sometimes organizations use help from an external consultant in deploying Six Sigma. Others may designate a leader from within the organization to act as Champion of the deployment. It is extremely important for an organization to make sure that the consultant or internal Champion understands the purpose of the deployment, as well as the context and culture of the organization.

The consultants or internal Champions must not dump all of their knowledge onto the team members at once. Training needs to be flexible according to the participants’ work schedules and carefully designed and delivered, with relevant examples and exercises that suit the business context.

Six Sigma training and mentoring should consist of more than mere academic modules on statistics. The objective should be to transform people into knowledge assets in the areas of root-cause analysis, innovative problem solving and process improvements so that they can bring value to the organization.

Recognition and Celebration

Finally, the management team needs to make sure that there is timely recognition of the effort put in by the project teams and that they are rewarded as per the organization’s policies and strategy. The celebration and evangelization of “wins” in a Six Sigma project can generate interest and inspire people to contribute to the organization’s journey of excellence.

Remember that the benefits of Six Sigma can include breakthrough improvements, cost savings, defect reduction and greater customer satisfaction.

Chapter 12: You Can’t Manage What you Can’t Measure

This axiom, while intuitive for most managers and business professionals, is often not applied to the Six Sigma management process itself. For Six Sigma or any other management initiative to yield the advertised results, many factors must be considered, aligned, measured and acted upon. Having been involved with Six Sigma as a consultant to a dozens of companies, I have been in a position to experience a variety of cultures and management systems and their linkage to quantitative results. While there are tremendous differences in management styles and priorities from company to company, one thing is clear. The organizations that focused on continuously measuring and driving management behaviours, including aligning initiatives and priorities, yield a much higher return on their programs than those who leave it to chance.

Consider the cost savings most often discussed in the annual reports of the best Six Sigma companies. They are usually discussing savings in a range of 2 – 3% of sales per year. At 3% of sales this adds as much as 10% per year to operating margin. Motorola reported, through their Six Sigma briefings, that savings for a 10-year period from 1985 to 1995 were $11 billion. GE in 1999 reported $2 billion in savings attributable to Six Sigma, and in their 2001 annual report discussed the completion of over 6,000 Six Sigma projects probably yielding over $3 billion in savings by conservative estimates.

Other organizations that have adopted Six Sigma have experienced far lesser amounts of financial success and organizational “buy in”. Many have Six Sigma savings in the range of 0.5% to 1.0% of sales (far less than the benchmarks mentioned above). There have even been cases where entire Six Sigma programs have been scrapped after significant investment due to low returns. How is this possible? Review of these failures and shortfalls has generally concluded that the lack of attention to the Critical Success Factors, for a sustained period of time, created a management vacuum around the program. Thus, the reactive culture that Six Sigma normally ferrets out through attention to data driven analysis returned and overcame the Six Sigma initiative. It’s human nature to revert to the old way (the comfortable way) of doing things when under stress.

The positive results don’t come easy and are driven by many factors besides management alignment. Without the statistics, the Black Belts, the projects, and the training, none of these results can be realized. But equally, the lack of alignment between people, strategy, customers and processes can quickly derail the best-intentioned initiative and quickly divert the attention of management.

Critical Success Factors and Focus

During most Six Sigma Executive and Champion training events some discussion of Critical Success Factors takes place. These discussions vary greatly in depth of coverage but usually include a variety of content on.

Executive Engagement

Management Involvement

Communications

Resources

Projects

Discipline and Consequences.

Each one of these Critical Success Factors may be broken down into sub-factors to further define the actions, measurements, roles, responsibilities and behaviours that each slice of the organization must demonstrate to assure success and get significant results.

Let’s examine a few Critical Success Factors and their associated sub-factors a little more closely and for clarification.

Critical Success Factor – Executive Engagement

Visible, consistent support and an active role in communication and reward.

Assuring linkage of Six Sigma to corporate strategies.

Clear prioritization (relative to other initiatives, programs and priorities).

Requiring the use of facts and data to support actions at all levels of decision-making.

Creating accountabilities, expectations, roles and responsibilities for the organization.

Conducting and attending regular reviews to assure and verify progress.

Critical Success Factor – Communications

Creation and communication of a Human Resources plan to support Six Sigma roles.

Regular written communications on Six Sigma news and successes.

Development and dissemination of communication aids to management.

Advocating and creating a “common language” based on Six Sigma.

Communicating pertinent facts about Six Sigma in every company meeting.

Critical Success Factor – Projects

Establish a documented 1-year Six Sigma project inventory (and refresh regularly).

Assure linkage of Six Sigma projects to critical business and customer needs.

Establish projects of appropriate scope and size (significant savings & achievable).

Assign a Champion and Black Belt to each project (and hold them accountable).

Implement a project tracking system to facilitate replication and reuse.

The documentation of these Critical Success Factors and their sub-factors is merely a first step in the process of assuring their implementation and making them a permanent part of a company’s culture and operating system. There is also the issue of assuring their effectiveness and use by the appropriate members of the target organization. Traditional methods of monitoring management behaviours have been largely subjective. There are systems that use Scorecards with red, yellow and green indicators. Still others that simply use check lists. It has occurred to many of us involved in Six Sigma that a better and more quantitative method for measuring, aligning and closing gaps in management performance and behaviour are needed. Especially considering that Six Sigma requires fact and data based decision making and performance enhancement.

The Power of Alignment

A good friend introduced me to the concept of Organizational Alignment several years ago. In his book, The Power of Alignment (John Wiley & Sons, 1998), he presents a compelling case for the need for Organizational Alignment and highlights 30 years of research connecting alignment to success.

The basis of his alignment concept is to collect a large sample of data from the various layers of an organization based around a series of factors and sub-factors. The data is objective in that instead of asking people how they “think they are doing with their own work,” you ask employees and management how the organization is doing with its work around a set of specific statements. That data is referenced to a quantitative scale (0-7 for example) and the sub-factors are defined in such a way that the responses may be “drilled,” demographically sorted, summarized and analyzed.

When this data is statistically analyzed and displayed many strengths, weaknesses and gaps can be visually displayed. Because George was a fighter pilot for the United States Air Force he likes to look at things from the perspective of a “target.” Applying this to management alignment, his preferred display was one that plotted a “numerical gap analysis” on a radar type of chart. The closer that the scores are toward the middle of the target, the tighter the alignment and the higher the probability of success. The United States Navy and Federal Express, to mention a couple of companies, have used the concept successfully.

Application to Six Sigma

While using this tool several years ago it seemed that this would be a great application and tool to measure, monitor and improve both the alignment and behaviours of an organization implementing Six Sigma. In “troubleshooting” issues with a Six Sigma deployment, imagine if you had a database with responses from hundreds or even thousands of employees. Imagine if you had statistical data that showed you that “Black Belts were adequately trained in all appropriate skills”, “Senior Management was engaged” but “Champions were not.” Then you could sort by Division or Plant to see if the behaviours were Companywide or isolated. This example illustrates how an organization could effectively drive very pointed actions over time using this concept.

With the proliferation of web based tools, measuring, managing and improving with data has become easier and much more efficient. If your organization, large or small, has a Six Sigma program in place, you should be measuring your return on investment (ROI) and determining whether or not it is achieving the benchmark levels mentioned at the beginning of this chapter. If it’s not, consider what your Six Sigma Critical Success Factors are, and ask how you are doing against them. Further, ask how you are measuring them and using them to drive optimization. I guarantee that if you are not getting benchmark results from your Six Sigma process, the definition, management and optimization of the Critical Success Factors are the place to look.

Universal Critical Success Factors

Accepting the General Electric definition of Six Sigma as “completely satisfying customers’ needs profitably” means that Six Sigma requires a company-wide initiative to dramatically improve process performance. It means that every employee in a company learns a structured approach to managing improvement projects and solving problems using facts and taking the customer’s perspective. It means on-target performance with minimum variation. With those givens in mind, here are some of the factors of Six Sigma which are considered universal.

Clear Project Chartering and Sponsorship

Defining the business case for the project, scope, baseline measures, resources required, potential risks and naming a senior executive as mentor/sponsor for the life of the project.

Identification of Customers and Their Needs

Identifying who receives the outcome of the process and what is critical to quality from their perspective.

Application of Measures

Describing the outcomes (Ys), process and input (x’s) measures upon which the project will focus.

Analysis of Causal Variables

Using quantitative methods to define causal relationships and the vital few variables that impact the desired outcome.

Improvement of Mean Performance and Sigma

Levels Reducing variability, not just average performance.

Standardization and Application of Control Charts

Putting in place the tools to track performance on an ongoing basis.

Case studies of two European companies show how they successfully maintained these foundation elements yet adapted Six Sigma to their national and company cultures.

Siemens

Business Improvement with Six Sigma as Toolkit

Siemens is an example of a German multinational company that carefully thought through its approach to Six Sigma, with a focus on improving collective business performance. Important to Siemens was how Six Sigma fits with other improvement initiatives such as ISO 9000 or the European Foundation for Quality Management (EFQM) Business Excellence Model. Not one to take on the “flavour of the month,” Siemens carefully assessed what contribution Six Sigma could make and integrated it into a comprehensive, logical approach to improvement called Top+ Quality.

The benefit of the Siemens approach is the top-down link to business improvement objectives, the distinction between process/input levers and other levers which are important but not suited for Six Sigma, and finally the highlighting of senior management’s role throughout the process. By positioning Six Sigma as a toolkit in a larger improvement methodology, Siemens concentrates on overall business improvement and effectiveness.

Ericsson

A Vehicle for Individual and Organizational Change

Ericsson is a Swedish multinational that is an example of a company Ericsson whose approach to Six Sigma balances the needs of the company with the needs of the individuals on whose support success depends. Because implementing Six Sigma often entails radical changes, receptivity to change for an individual as well as an organization is an important predictor of success.

In addition, because Ericsson recognizes the need to engage on the individual level, it designed its Six Sigma training with an opportunity for “contracting” between project leaders and their managers. The manager of each participant in a Six Sigma Black Belt course attends one day during the first week of training. This gives time off-line for the manager to clarify a number of critical elements, why the person was selected, why the project was chosen, how the success or failure of the project will affect the individual’s career. Likewise, the project leader can negotiate for the time needed to work on the project assignment and the support he/she will need from the supervisor. Particularly in companies where Black Belts are balancing project work with operational responsibilities, contracting for time to work on assignments is vital to the success of Six Sigma.

Ericsson demystified change in measurable and practical terms. By weaving change management modules and contracting sessions into Six Sigma training Ericsson significantly increased the probability of success.

Uncompromising yet Flexible

Bedrock principles of Six Sigma should not to be compromised regardless of the country. However, to be successful, a company has to fit Six Sigma into the organizational and cultural context in which it is working. In Germany, support for Six Sigma is gained by showing how it relates to an integrated concept of improvement. This includes acknowledging the value of existing approaches, and clarifying both the ultimate goal and the steps for getting there. In Scandinavia, the focus must be on the individual and the benefits that Six Sigma offers him/her. This includes de-emphasizing “stretch goals” imposed from above, communicating the personal development the individual acquires through Six Sigma, and acknowledging and working with the factors that influence the capability to change.

The art of successfully implementing Six Sigma is to be uncompromising about the critical ingredients for success while being flexible to the cultural context in which one is working.

Chapter 13: Driving Six Sigma Success without Top-level Support